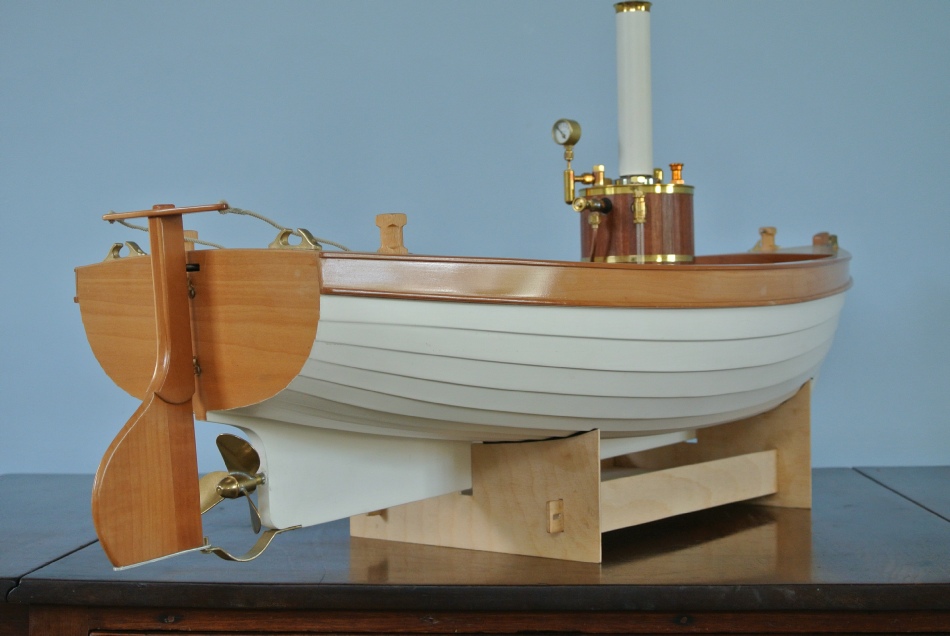

The ‘Henry’

The deck house lifts off for access to the removable gas cylinder and the gas attenuator.

The rudder, transom, bulkheads, interior benches, coal boxes and sheerstrake are

constructed from various thickness of pre-

The floors and splash guards next the engine are wood laminated onto pre-

Scale -

Length Overall:-

Max Beam over rubbing strake -

Max draft over skeg -

MAX Displacement -

The hull is an epoxy resin fibreglass moulding. The keel is constructed from three

pre-

Various sizes of pear and lime strip are provided. The fairleads and skeg are brass

castings. The bitts are pre-

(Note: Cordage not provided)

Internal construction showing servo placement

Radio control layout in stern of model.

(Note -

Foredeck detail

Marten & Howes